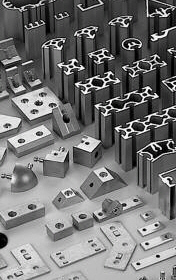

T-slot framing is a technology that is widely used for industrial automation, robotics and machine enclosures for the past 30 years. Lately, these framing systems have been increasingly miniaturized and their purchase cost has dropped significantly. Not only they are small enough to work as model building system, but they are also precise and strong enough to build real machines and robots.

The T-slot framing system consists of square extruded aluminum beams, various connectors and the hardware necessary to build just about anything. The modularity of extruded aluminum profiles is based upon the T-slot concept of their profiles. The “T” shaped slots present on all sides, allow for infinite positioning along the axis.

Recently several proposals have appeared on the market and thanks to their versatility and their affordable price, they have become an optimal solutions to many applications.

These are only four of the several possible proposals:

- MakerBeam

- OpenBeam

- MicroMax

- 80/20

In the following figure Micromax, MakerBeam and OpenBeam profile’s sections are shown below in scale. Micromax and MakerBeam profiles have a square section of 1cm of side, instead OpenBeam has a square section of 1.5cm of side.

The follow figure (Fig.3) shows how T-slot and T-nut are conceived in MakerBeam:

and in Fig.4 it is shown how MicroMax conceives the T-slot framing:

and finally, Fig.5 shows how T-Slot and T-nut are conceived in OpenBeam.

As we can see, these are three different ways of thinking about the use of the T-slots.

The MicroRax and OpenBeam use of the nut-bolt couple is perfectly the opposite of that conceived in MakerBeam. It is the T-nut to be in the T-slot and not the head of the bolt. Furthermore, in the OpenBeam T-slot, the T-nut is a normal M2 nut, you can purchase it at any hardware store! In fact in OpenBeam aluminum profiles the T-slot is designed to fit the size of a M2 nut.

The Starter Kits

Once we made our choice and we decided which of these systems meets our needs, it is advisable to start with the purchase of a Starter Kit. These kits contain a series of elements which generally able you to develop almost any project. If you want to go further, you can always supplement the kit ordering the pieces that we need more.

The T-Slot framing components

FASTENERS

There are many types of fasteners that can be adapted to be used with T-slots, each of them will prove to be more or less suitable to different functions. Here we see some different ways of conceiving the nut inside the T-slot (referring to it as the T-nut).

Slide-In T-Nuts

Slide-in T-nuts are those that must be loaded in the end of the T-slotted profile. In this case, preloading is necessary during assembly.

Drop-in T-Nuts

Drop-in T-Nuts are designed to load straight into the opening of the T-slot, then rotate until engagement. The width of a Drop-in T-Nut must be less than the T-slot opening dimension.

Roll-in T-Nuts

Roll-in T-Nuts are unique due to their ability to load in the T-slot from the face of the profile. A rolling or rotating motion is performed to install these in the T-slot.

Self Aligning T-Nuts

Self-Aligning T-Nuts have a raised section that extends up into the T-slot opening. Theis neck is engaged and aligned with the T-slot when secured in its tightened position. This feature will center the threaded hole of the T-nut in the T-slot, prevent rotation and allow for longer thread dimensions.

JOINING PLATES

Joining plates allow you to connect frame members without additional machining services.

For example in the MakerBeam kits there are joining plates with different angles.

PANELS AND DOORS

It is possible to create enclosed volumes such as containers, boxes and cabinets using hinges, panels, brackets and handles.

In fact, it is possible to enclose panels into square frame inserting their outer edges inside the T-slots.

This is an example of what can be done enclosing panels into aluminum frames. This is the tutorial (using MicroRax aluminum profile).

Extend your possibilities

Motor mounts can bolt directly to the beams and with the use of angle brackets, you can mount any kind of motor. A common case is the use of NEMA 17 stepper motors for building 3D Printers, but you can use DC motors and Servo Motors as well.

Another example, it is the integration of printed circuit boards with T-slot framing. In fact, it is possible to slide a PCB into the beams.

But if this don’t work well, you can mount a PCB on spacers bolted onto the T-slot:

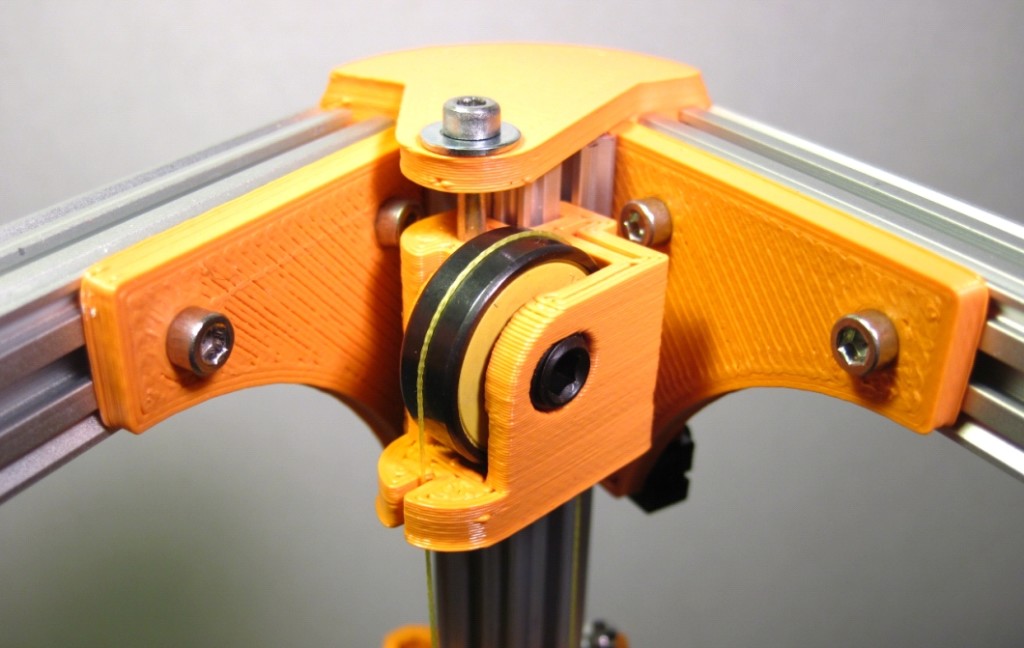

Other mechanical components are compatible with the T-slot framing. You can add pulleys, belts, rods, bearings, sensors and so on.

Exceed All Limits!

There is absolutely no end to what can be done with it. Because OpenBeam and MakerBeam are open-source, you can develop and build your own pieces to interlink, even further expanding the possibilities. In fact, if you have a 3D printer then there are no limits to what you can create. This will give you the ability to implement multiple integrated solutions using both aluminum profiles and 3D-printed plastic parts.

[:]