Introduction

We have now arrived nearly at the end of 2014, and like every year with the imminent arrival of the Christmas holidays the problem of decorative lights becomes very timely: stars, wires, waterfalls, puppets, pinwheels, and for use indoors and for those outdoors. This article will be a useful support for all those who directly or indirectly are involved in their use, especially for all those people who are going to make the happiness of many children getting ready to illuminate trees, nativity scenes, balconies, facades, gardens ( Fig.1 shows some examples of Christmas decorations bright)

The technical features

The decorative lights more commonly known as luminarie are purely temporary electrical installations, generally made of a set of chains of lights fed by an electric plant and installed in public and / or private, outdoor (streets, squares, parks, monuments, gardens, balconies, facades) or inside (shopping centers, shops, offices, homes). The decorative lights are in effect considered electrical components and then from the regulatory point of view they are equivalent to lighting devices, and therefore have to be manufactured in compliance with:

- EN 60598-1 “Luminaires – General requirements and tests” implemented by the CEI 34-21 applies to luminaires for incandescent, fluorescent and other discharge lamps, with a supply voltage not exceeding 1000 V;

- EN 60598-2-20 “Luminaires – Particular requirements – Lighting chains” implemented by the CEI 34-37 applies to chains with bright incandescent lamps connected in series or in parallel indoors or outdoors and fed a voltage not exceeding 250 V .

Under the same rules must also respond to the illuminations assembled “in situ” to fit the features of buildings, for example for the decoration of buildings, monuments, homes. In this case, the installer will assume the role of manufacturer with the assumption of its liabilities.

Since 1993, in respect of the freedom of movement in all countries of the European Union, you can apply the ENEC (European Norms Electrical Certification) on lights. It is a mark of quality on a voluntary basis, based on very strict criteria for the grant with which the manufacturer certifies that a product complies with EN 60598 and provides the end user the maximum guarantee with regard to electrical safety and procedures in the realization of the products. In addition to the manufacturers of lighting fixtures also manufacturers of power factor correction capacitors, lamp holders, holder, starter, ballasts, ignitors may request permission to use the ENEC

The ENEC mark has been set up at the CENELEC (European Committee for Electrotechnical Standardization) by certifying bodies for electrical certification, which in June 1992 entered into an agreement called “Lum Agreement” with which it has been recognized one brand equivalent to individual brands of the certifying bodies members. Its administrative management has been assigned to the EEPCA (European Electrical Products Certification Association) association.

To get the ENEC markthe manufacturer must:

- have a quality system complies with ISO 9001: 2000;

- make products in accordance with EN 60598;

- subjecting the products to the surveillance of the certifying body throughout the production process.

With the agreement “Lum Agreement” has been established that the ENEC Mark may be issued by any of the relevant European electricity certified members and it must therefore be recognized by all other organisms. To identify the organization that issued the certificate, you must put alongside ENEC an identification number based on the country of origin as shown in Table 1. (Some brands with the identification number of the body that issued it can be seen in Fig 1).

| ID | Certifier | Country |

| 01 | AENOR | Spain |

| 02 | CEBEC | Belgium |

| 03 | IMQ | Italy |

| 04 | IPQ | Portugal |

| 05 | KEMA | Holland |

| 06 | NSAI | Ireland |

| 07 | SEE | Luxembourg |

| 08 | LCIE | France |

| 09 | ELOT | Greece |

| 10 | VDE | Germany |

| 11 | OVE | Austria |

| 12 | BSI | United Kingdom |

| 13 | SEV | Switzerland |

| 14 | SEMKO | Sweden |

| 15 | DEMKO | Danmark |

| 16 | FIMKO | Finland |

| 17 | NEMKO | Norway |

| 18 | MEEI | Hungary |

| 19 | BEAB | United Kingdom |

| 20 | ASTA | United Kingdom |

| 21 | EZU | Czech Republic |

| 22 | SIQ | Slovenia |

Table1: ID numbers associated with the ENEC

All electrical and electronic equipment including lighting, for free movement within the European Union, must also comply with Directive 2011/65 / EU of 8 June 2011 called RoHS 2 (Restriction of Hazardous Substances) “Restriction the use of certain hazardous substances in electrical and electronic equipment “acknowledged in Italy with Law Decree 27/2014 (replacing Directive 2002/95 / EC RoHS called first implemented in Italy by Legislative Decree 151/2005). The new RoHS Directive introduces the following obligations for manufacturers and / or importers and / or distributors:

- preparation of a statement of compliance or total exclusion of any type of warning and / or limitations;

- conservation of the declaration of conformity for 10 years from the date of placing the product on the market;

- affixing of the CE marking on the products;

- affixing of their data with relevant address on the products in order to provide always a point of contact with the user;

- carry out checks during the manufacturing process to ensure that products containing high percentages of hazardous substances prohibited are not marketed. Substances such as mercury, cadmium, lead, hexavalent chromium, polybrominated biphenyls (PBBs), polybrominated biphenyl ethers (PBDEs);

- preparation of a technical dossier of information in the native language of marketing including the documentation required to demonstrate compliance of the various materials that make up the product.

Typically the lights are made with light chains consist of a set of white bulbs or colored. In recent years, however, due to the development of advanced manufacturing technology and publication of the latest standards for energy efficiency, the common incandescent bulbs have been replaced by halogen lamps and especially the multicolored ultra-low power LEDs that are more expensive than the sources traditional light but offer energy savings of about 85%. The electrical connection of the various components of the bright lights can be made:

- in series. The bulbs are connected one after the other to form a ring, for which according to the second principle of Kirchhoff relative to the meshes, each bulb is subjected to a voltage equal to the total voltage power divided by the number of bulbs that constitute the chain. In these chains directions with the characteristics of the bulbs should be shown in a clearly visible in order to avoid the wrong replacement by other unsuitable. This type of connection uses low voltage bulbs whose number is limited by the value of the supply voltage and in case of failure of one of them shuts off the entire chain (see figure 3). For these reasons, the series is mainly used for small light chains in the home, shops or offices;

- in parallel. Each bulb is connected directly to the mains voltage. The various electrical nodes that are created for each bulb shall respect the first principle of Kirchhoff for the nodes, and consequently the power supply wires must travel the entire length of the chain, and must be dimensioned to withstand a total current resulting from the sum of the individual current of each bulb used. With this type of connection, the number of bulbs can be unlimited and in case of failure of a bulb the others remain lit, (see figure 4). For this flexibility the system of parallel connection is used for those illuminations installed in streets, squares, monuments, fountains, where it is also necessary to limit maintenance.

From the functional point of view the illuminations can be:

- demountable. They are constructed in such a way that all components can be replaced (see figure 5);

- not-demountable. No component can be separated and replaced by light chain ( see Figure 6);

- sealed. For example, those strung in tubes transparent insulating rigid or flexible, sealed at the ends and without junctions (see figure 7);

- for internal use. Can only be used indoors without humidity, see figure 8;

- for outdoor use. They can be used outdoors and are protected from entry of very small solid bodies and / or spray and water jets, ( see Figure 9 ).

Applicable Reference Standards

Before listing the standard rules relating to the lights, it is good to clarify that they are a useful tool to ensure a sufficient level of safety as well as for the product also for the relationship between the manufacturer and the user. In Italy with Law 186 of 1968 recognizes the CEI (Italian Electrotechnical Committee) as Italian standardization body for the electrotechnical industry but especially recognized the presumption of conformity with good rule of art for all that is done in accordance with CEI .

This means that compliance with the regulations issued by the Italian Electrotechnical Committee must be considered sufficient, but not necessary in order to ensure an acceptable level of safety. That is, if they are applied in full the project and / or the installation and / or the various components may be considered perfectly satisfying to a acceptable level of safety such that you do not incur any civil penalty and / or criminal penalties. Whereas if you apply technical solutions other than those required by the standards the designer and / or installer and / or the builder are jointly and severally liable in civil and criminal.

Accordingly, in the specific case of the illuminations you can apply the following standards:

- EC Low Voltage Directive 95/2006;

- EC Electromagnetic Compatibility Directive 108/2004;

- Law # 791 of 18.10.1977 implementing Directive 72/23 / EEC;

- D. L. 6/11/2007 194 of the implementation of the EC Directive 108/2004;

- EN 60598-1 Luminaires – General requirements and tests;

- EN 60598-2-20 Luminaires – Particular requirements – Lighting chains;

- IEC 61347-2-11 Control devices for lamps – Particular requirements for electronic circuits used with heterogeneous luminaires;

- EN 55015 Limits and methods of measurement of radio disturbance characteristics of electrical lighting and similar equipment;

- EN 61000-3-2 – Limits for harmonic current emissions;

- EN 61000-3-3 Electromagnetic compatibility – Limitation of voltage changes, voltage fluctuations and flicker in low-voltage supply systems;

- EN 61547 Equipment for general lighting purposes – EMC immunity requirements;

- IEC 529 and EN 60529 Degrees of protection provided by enclosures;

- CEI 11-4 “Technical standards for the construction of overhead power lines outside”;

- CEI 64-7 “Plant public lighting series fed.”

Electromagnetic compatibility does not apply to chains with bright incandescent lamps (now replaced by those halogen) without electronic devices. For light chains of class III to EN 61558-2-6 is applied “Safety of transformers, reactors, power supply units and similar products for voltages up to 1100 V – Particular requirements and tests for isolating transformers and safety supply units incorporating safety isolating transformers “.

The main regulatory requirements

The light chains must meet the following regulatory requirements:

- They must be powered by its own supply when installed on public ground, in this case is not allowed to connect to the provision of public lighting;

- if they are installed in public places and temporarily fed by the distributor, they are not subject to the DM 37/08, while if they are installed in private homes, such as stores, shopping centers, housing, they vpossono be connected to the same electrical system of the building and therefore are subject to the DM 37/08, see Figures 10 and 11;

- If installed outdoors, they must be protected against solid objects larger than 1 mm and against the rain or splashing water with protection increased (Increased Protection) IP43 or IP44, including junction boxes and plugs which can be also of domestic type. Depending on the installation location, such as near the fountains, areas with continuous presence of snow, dusty environments, it is advisable to also protect them against dust and water jets with IP55 protection, see table 2;

| Degree of protection (IP Increased Protection – Increased Protection) | |||||

| First digit protection against ingress of foreign objects and access to hazardous parts | Second digit protection against water penetration | ||||

| 0 | No protection | 0 | No protection | ||

| 1 | Protected against solid objects larger than 50 mm | Human body parts or solid bodies larger than 50 mm in diameter must not be able to penetrate | 1 | Protected against vertically falling water drops | The drops of water falling vertically must not cause harmful effects |

| 2 | Protected against solid objects larger than 12 mm | The fingers or the like of a length not exceeding 80 mm or solid bodies of diameter greater than 12 mm should not be able to penetrate | 2 | Protected against water with maximum inclination of 15 degrees | The drops of water falling vertically must not cause harmful effects when the enclosure is tilted at any angle up to 15 degrees with respect to its original position |

| 3 | Protected against solid objects larger than 2.5 mm | Wire diameter or thickness greater than 2.5 mm or solid bodies with a diameter greater than 2.5 mm should not be able to penetrate | 3 | Protected against rain | The water that falls in rain with a direction forming an angle with the vertical to 60 degrees may not cause harmful effects |

| 4 | Protected against solid objects larger than 1 mm | Wires or flat plates of a diameter or thickness greater than 1 mm or solid bodies with a diameter greater than 1 mm must not be able to penetrate | 4 | Protected against splashing water | Water projected by a nozzle on the housing from all directions must not be harmful |

| 5 | Protected against dust | The penetration of dust is not totally excluded but the amount entered is not likely to affect the sound operation of the material | 5 | Protected against water jets | Water projected by a nozzle on the housing from all directions must not be harmful |

| 6 | Totally protected against dust | There shall be no penetration of dust | 6 | Protected against powerful water jets | In the case of waves or powerful jets, the water should not penetrate the enclosure in harmful quantities |

| 7 | Protected against the effects of temporary submersion | the penetration of water in harmful quantity inside the immersed under defined conditions of pressure and time shall not be possible | |||

| 8 | Protected against the effects of continuous submersion | The material is suitable to be submerged in water under the conditions specified by the manufacturer |

Table 2 Number of extra protection IP

- Class II (double insulated) or class III safety extra low voltage SELV (Safety Extra Low Voltage, 50 V);

- for lighting chains classified Outdoor, gaskets must adhere perfectly around the bulbs, they must withstand weather changes and must remain on the bulb holder also extracted;

- if realized with lamps in series, they must bring with a special plate located preferably in the vicinity of the power plug, indications about the voltage of the bulbs in order to avoid the substitution of other non-suitable;

- if not made in class III, they must have a power cord rubber H05RN-F or equivalent, the minimum length of 1.5 m and a maximum of 3 m from plug to first bulb; in case of power cables longer than 3 m cable must be rubber H07RN-F or equivalent;

- the management of Waste Electrical and Electronic Equipment (WEEE), in this case the lighting equipment in Europe is regulated by Directive 2012/19 / EU (replaces the 2002/96 / EU and 2003/108 / EU) which provides indications on joint management of WEEE in order to achieve objectives such as recycling and recovery of valuable secondary raw materials, the reduction of hazardous substances, reducing the volume of electrical and electronic waste to be disposed of. In Italy the EU directives have been implemented before the DL 151 of 25/11/2005 and recently replaced with DL 49 of 14/03/2014. The Decree provides the following definitions:

electrical and electronic equipment “equipment which is dependent, for a correct operation, electric currents or electromagnetic fields and equipment for the generation transfer and measurement of such currents and fields and designed for use with a voltage not exceeding 1000 volts for alternating current and 1500 volts for direct current “;

waste electrical and electronic equipment or WEEE “the electrical or electronic equipment which is waste within the meaning of Article 183, paragraph 1, letter a) of Legislative Decree 3 April 2006, n. 152, including all components, subassemblies and consumables which are part of the product at the time when the holder discards, intends or is required to discard. “

The decree also stipulates that it is absolutely forbidden to treat WEEE as unsorted municipal waste, the presence of harmful substances such as lead, cadmium, mercury, hexavalent chromium, which makes them extremely dangerous for end of life must be compulsorily collected from ecological municipal pitches before being sent to special collection centers and recovery borne by producers who are obliged to put on the product a specific symbol to indicate that at the end of life, the light chain will have to be collected separately and should not be treated as a household waste.

For this reason, all electrical and electronic equipment must show in a clear, visible and indelible manufacturer name and the symbol of Figure 12, which indicates that the equipment must be disposed of separately. If not possible you have to apply the symbol directly on the product. It must be present and clearly shown on the packaging and / or instructions and / or on the warranty, supervision Law Enforcement WEEE is handled by the Ministry of Industry. The Decree also provides for the obligation for producers to join a collective system for the management of WEEE, depending on the type of equipment or type of market served, the main collective system operating in Italy for the recovery and disposal of equipment lighting is the Ecolamp consortium, while that for the recovery and disposal of WEEE generic is the consortium Apiraee.

- essere installate con funi di sostegno in nylon o metallo adeguatamente isolato, il carico di rottura della fune di sostegno deve essere di almeno 20 volte il peso della catena luminosa con un minimo di 400 kg, mentre i sostegni della fune devono garantire una resistenza meccanica superiore a quella della fune. I pali di sostegno delle linee elettriche aeree non possono essere usati per ancorare le luminarie, fatto salvo il caso che le linee siano in cavo e si abbia il consenso del Distributore, lo stesso vale per i pali dell’illuminazione pubblica, fatto salvo il caso che si abbia il permesso del comune di competenza;

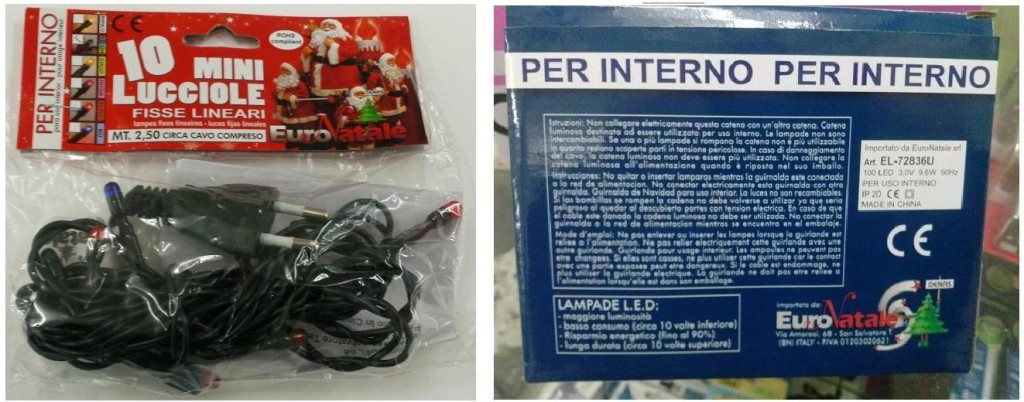

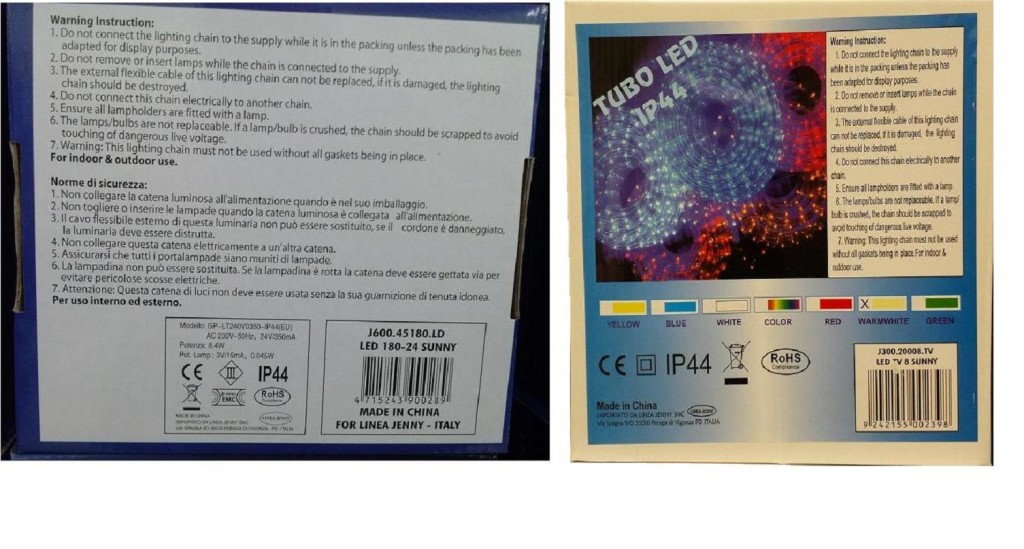

- luminous chains, as they are considered electrical components, are subject to the Low Voltage Directive and the RoHS Directive and shall be identified with a special label, in a clearly visible, the following information provided to the lighting fixtures, see Figures 13 and 14:

- CE marking and mark of origin of the manufacturer;

- graphic sign for Class II or III;

- IP protection with the words “for internal use” or “for external use”;

- the rated voltage for the light chains of class III.

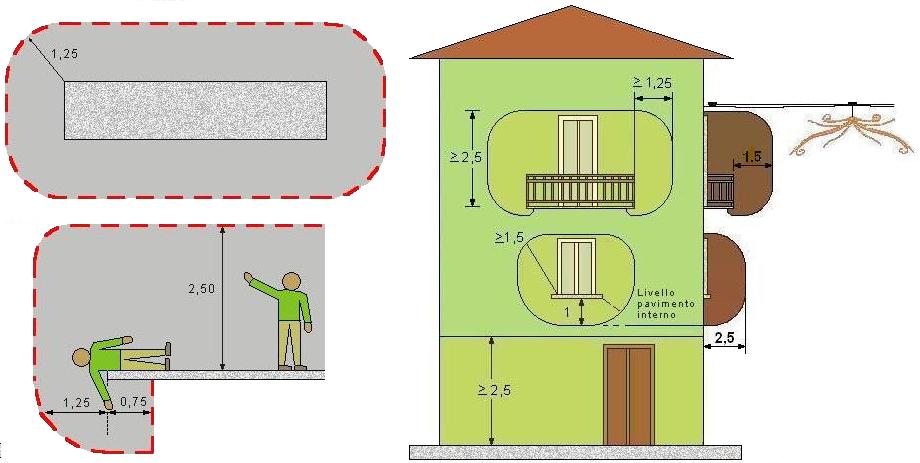

Distances recommended installation

The CEI 34-37 does not provide special instructions regarding the installation height of the illuminations that still need to be installed:

- so as not to cause obstruction to the passage or create problems for the safety of persons and other plants;

- according to the requirements of IEC 11-4 on the execution of the overhead power lines outside, see figure 15;

- according to the requirements of IEC 64-8 for areas “within reach” if it is operated at 230 V, see figure 16.

With regard to installation distances, for the lights cutlery in public areas you must also respect any municipal ordinances, provincial and regional. If you need to install, for logistical reasons, an illumination powered by 230V with reach, standards recommend the adoption of a mechanical protection and a differential switch with operating current not exceeding 30 mA. If the light chains are class III safety extra low voltage (SELV) can be installed at hand. In case of the proximity of a luminaria to a power line overhead cable, the standard does not indicate the minimum distances, it is sufficient that the electrical line and the illuminations are not in contact. Particularly recommended are the following distances from the ground and from other plants:

- electrical cables and of the cables supporting the illuminations crossing the roadway should be at least 6 m in height, while the light emitting elements must be with the lower part to not less than 5.20 m in height;

- the lights should be installed at the following distances from other installations: at least 1 m from overhead power lines of Category I, by trolleybus or tram lines, telephone lines bare; least 1.8 m from conductors of airlines in category II; at least 3.2 m from its poles or pylons;

- anchorages support cables or lights must be at least 0.2 m from the telephone lines;

- multicore cables of section up to 10mm2 can be laid without carrying cable with span not exceeding 25 m, must be type H07RN-F or similar and can be fixed to the wall with suitable staples, the voltage drop may exceed the acceptable 4% up to a maximum of 10%.

Use instructions and recommendations

While the lights installed in public places (squares, streets, monuments, parks, fountains, etc.), in almost all cases (except for small municipalities where it is still practice the use of employees handyman, mason from the painter until the electrician and the gardener) the lights are assembled, installed and certified by companies with qualified personnel and subject to specific regulations and controls which permits local and municipal regulations, the domestic private and generally are the most at risk because they often made electric and / or used improperly. To prevent accidents at home as electric shock, short circuits and especially fires, it is preferable to buy safe products, manufactured according to current regulations and which are presented in a clearly visible the following information:

- the electrical characteristics of the lamps and the rated voltage of the chain;

- Class II (double insulated) or III (SELV);

- the warning “for internal use” or “for external use”;

- the presence of the CE marking is a mandatory administrative condition necessary for the free movement of products within the European community and indicates compliance with the safety requirements of EU directives;

- the presence of a certification mark, such as IMQ or ENEC, which certifies that the product has been subjected to the tests to verify compliance with the rules in force;

- the presence of a statement of compliance with the RoHS directive on the use of hazardous substances.

Lastly, there are some simple rules to be implemented especially in the home, office, small and medium businesses:

- purchase lights showing the CE mark on the packaging, which ensures compliance with the rules of manufacture, and any other quality brands such as ENEC and IMQ;

- before using the lights outdoors, make sure that the package is marked “for outdoor use” and this is the abbreviation IP43 or IP44;

- the laying of any type of luminaria, even in private areas, you must always keep in mind the existence of any specific regulations issued by municipalities or other local authorities responsible for the territory;

- to connect multiple light chains do not use a single outlet with its plug triple, but a power strip (strip) 2P + T 16 A sockets with P17 / 11 (bypass) and P30 (schuko), bright switch, homologation, alternatively use more taken with appropriate extensions;

- Indoors, you must use the lights in dry, place them away from heat sources such as cookers, stoves, heaters, but most do not always leave them on, if not of an appliance intermittent built should connect to mains supply via a specific plug / socket intermittently, see Figure 17;

- Always unplug the lights from the sockets whenever you are not present in the office, in the store or at home especially during the night, especially those used to light the tree and / or the crib and / or similar objects, because this typically the materials with which these objects are achieved often turn out to be highly flammable and is sufficient to trigger a small overheating a possible fire.